Nozzle Check Valves - Recommended by www.ValveDepot.com

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||

|

|

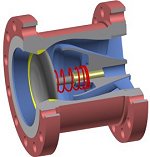

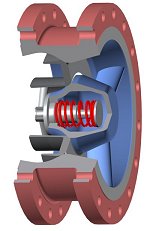

A further important factor in the present and future is economy (the savings of energy). A feature of the nozzle check valve DRV-Z is its inherent non ?slam characteristic. This is attained because the valve reacts so quickly to flow (velocity) changes that it is always able to outpace the process change and be at the point of closure before it is possible to obtain reverse flow. |

|

|

|

|

|

|

|

|

|

|

|

|

|

In liquids this avoids 攚ater hammer? and in gas it assures no chance of reverse flow into the compressor. Additional benefit of the nozzle check valve design is its extremly long service life because the moving parts are not subjected to the shocks associated with typical asymmetric valve designs. The valve has no soft parts to wear, cause misalignment, or need replacing. |

||||

|

|

|

||||||

|

|

|

The type DRV-Z can be installed in Water, Oil and LNG pump stations as well as in compressor stations. |

|

||||

|

|

|

|

|

|

|||

|

|

|

|

|||||

|

|

|

||||||

|

|

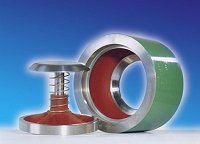

All Entech Meer designs are available in virtually any commercially available material suitable for casting and built and tested to widely accepted standards such as API 6D or DIN etc. ?br>Valves to other standards, testing qualification procedures are available to meet any requirement. |

|

|

||||

|

|

|

||||||

|

|

||||||||||||||||||||||||||||

|

|

The fluid will increase in velocity as it approaches the throat of the valve, then using the Venturi effect of the precisely prefiled surfaces of body and diffuser, high pressure recovery is achieved. As the fluid exits the valve its velocity and pressure is almost identical to its incoming conditions. As the flow velocity decreases the carefully selected helical spring acts on the disc moving it towards the closed position, due to the reduced opening force of the process fluid. With proper attention to the flow parameters the valve can achieve movement from fully open to fully closed in less than 0.1 seconds. |

|

|

|

|

|||||||||||||||||||||||||

|

|

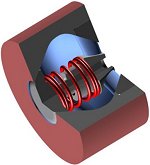

An additional benefit of the KRV valve design is its extremly long service life as the moving parts are not subjected to the shocks associated with typical asymmetric valve designs. |

|

|

|

|

|

|

|

|

Valves to other standards and testing qualification procedures are available to meet any requirement. |

|

|

|

|

|

Features |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

|||||||||

|

|

The Entech Meer wafer check valve type KRV was designed to meet three mandatory requirements : non ?slam, short installation length and no maintenance. This very space ?efficient non ?return valve is a compact, fully non ?slam valve and available for sizes from 1?up to 12?and all pressure classes. This superbly simple design allows the single axial disc to respond very quickly to any flow changes. This rapid response to process changes ensures the disc is correctly positioned at all times and is fundamental in achieving fully non ?slam closure. With proper attention to the flow parameters, the valve can achieve movement from fully open to fully closed in less than 0.1 seconds. |

|

|

|||||||

|

|

|

|||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

|

||||||||

|

|

|

|||||||||

|

|

The reduced length available within the valve for optimum pressure recovery is offset by the other installation advantages of the KRV design. The metal ?to ?metal sealing achieves tight shut ?off with 100% reliability and no weak link or soft seals to cause premature valve failure. The KRV check valve is suitable for installation in any position ( horizontal, vertical or inclined ). |

|

||||||||

|

|

|||||||||||||||||||||||||

|

|

This is attained because the valve reacts so quickly to flow (velocity) changes that it is always able to outpace the process change and to be at the point of closure before reserve flow can occur. |

|

|

||||||||||||||||||||

|

|

|

|

|

Valves to other standards and testing qualification procedures are available to meet any requirement. |

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

The metal-to-metal sealing achieves tight shut-off with 100% reliability and no weak link or soft seals to cause premature valve failure. The nozzle check valve is suitable for installation in any position (horizontal, vertical or inclined). |

|

|

|||||||||||||||||||||

|

|

|

|

|

The KRV-B provides: The dynamic behaviour of this type of check valve has been tested by independent hydraulic institutes. Test reports are available on request. |

|

|

|

|

|

|

|

|

|

|

|

|

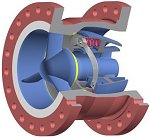

An additional benefit of this check valve design is its long service life as the moving parts are not subjected to the shocks associated with typical asymmetric valve designs and thanks to the smooth closing effect. |

|

||||||

|

|

|

|

|

|||||

|

|

|

Case histories are available where the KRV-B has been installed in piping systems worldwide. All Entech Meer designs are available in virtually any commercially available material suitable for casting and built and tested to widely accepted standards such as API 6D or DIN etc. ? |

|

|

||||

|

|

|

|||||||

|

|

||||||||

|

|

Valves to other standards and testing qualification procedures are available to meet any requirement. |

|

||||||

|

|

||||||||

|

|

Features |

|

||||||

|

|

|

|||||||

|

|

||||||||||||||||

|

|

The optimum dynamic design of the valve internal parts allows the disc to respond very quickly to any flow changes. This rapid response to process changes ensures that the disc is correctly positioned at all times and is fundamental to achieving fully non-slam closure. With proper attention to the flow parameters, the valve can achieve movement from fully open to fully closed in less than 0.15 seconds. |

|

|

|

|

|||||||||||||||||||||

|

|

|

|

|

This is attained because the valve reacts so quickly to flow (velocity) changes that it is always able to outpace the process change and to be at the point of closure before reserve flow can occur.In liquids this avoids water hammer and in gas it assures no chance of reverse flow. |

|

|

|

|

|

|

|

Valves to other standards and testing qualification procedures are available to meet any requirement. |

|

|

||||||||||||||||||||||||||||

|

|

This unique annular ring design outperforms other nozzle designs, particulary in larger valves, because the moving component (disc) has a very low mass and can move from fully open to fully closed very quickly by a friction-free action not attainable by centre shaft designs. In the fully open position, the disc and the diffuser form a perfect aerofoil section. This, combined with the increased nominal bore due to the oversize centre flange, achieves optimum pressure recovery. The uniform shape of the flow path through the entire valve ensures excellent stability for the moving disc which shadows any change in process flow rate, so being correctly positioned at all times. |

|

|

…… and more

Note: Request quotation for valves must use our Inquiry

System.

You will not get reply for pricing if just using direct email.

Ask Price of Valves click here (go Step #2)

or Contact us for other issues