Orbit

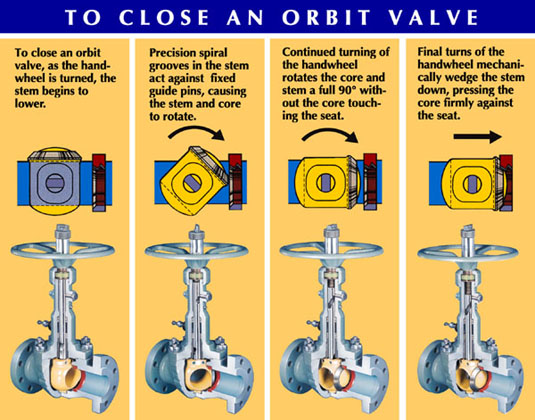

Every Orbit valve

incorporates a proven tilt-and-turn operation, that eliminates seal rubbing, which is the

primary cause of valve failure. When an Orbit valve is closed, the core is mechanically

wedged tightly against the seat, assuring positive shut-off. Every Orbit valve

incorporates a proven tilt-and-turn operation, that eliminates seal rubbing, which is the

primary cause of valve failure. When an Orbit valve is closed, the core is mechanically

wedged tightly against the seat, assuring positive shut-off.

When an Orbit valve begins to

open, the core tilts away from the seat and line flow passes uniformly around the core

face. This eliminates the localize high-velocity flow that typically creates uneven seat

wear in ordinary ball, gate and plug valves. The core then rotates to the full-open

position. When an Orbit valve begins to

open, the core tilts away from the seat and line flow passes uniformly around the core

face. This eliminates the localize high-velocity flow that typically creates uneven seat

wear in ordinary ball, gate and plug valves. The core then rotates to the full-open

position.

The absence of seal rubbing during both opening and closing means easy, low-torque

valve operation and long-term reliable performance.

When valve leakage cannot be tolerated, the Orbit operating principal can be relied

upon to deliver positive shut-off.

Orbit has resilient seals and all-metal seal options to cover the most aggressive and

challenging situations. Orbit valves are ideally suited for:

- flow lines

- meter isolation

- dryer switching

- block and bypass

- product segregation

- emergency shutdown

- suction and discharge isolation

- and many other applications

Orbit valves are without equal when zero leakage and frequent operation are demanded.

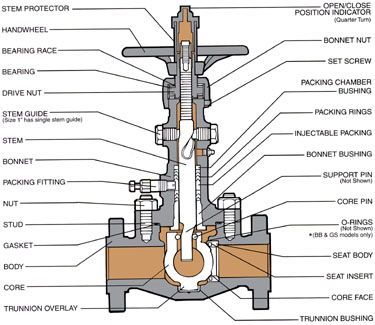

- Zero Leakage.

- Inherently firesafe design.

- Durable, rugged mechanism.

- In-line repairable.*

- Bi-directional, drop-tight seal.

- No springs or piston movement.

- Rated up to +427 C / +800 F.

- No localised high-velocity flow to erode seal during opening/closing

- Resilient seals are enclosed and protected.

- All-metal seat option provided reliable sealing in harsh, abrasive flow conditions.

- Gas-tight stem packing is certifiable to local emissions regulations.

*Never remove any part from an Orbit valve unless specifically

instructed to do so in Orbit literature, or without first consulting an Orbit

Representative. Incorrect procedure could result in personal injury and/or property

damage. |

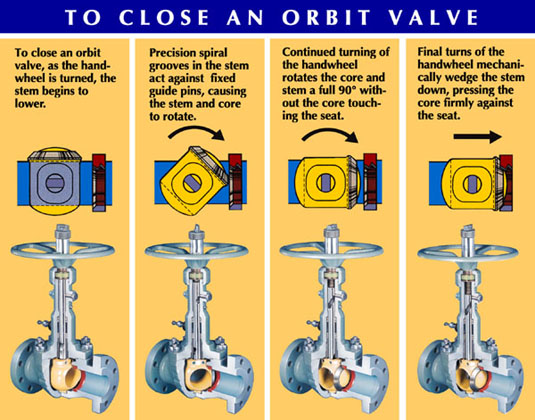

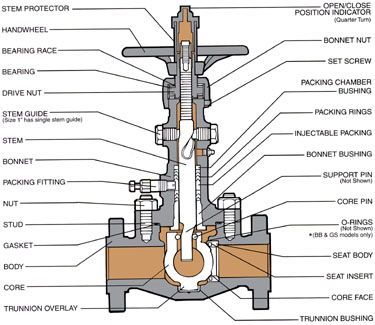

Every Orbit valve

incorporates a proven tilt-and-turn operation, that eliminates seal rubbing, which is the

primary cause of valve failure. When an Orbit valve is closed, the core is mechanically

wedged tightly against the seat, assuring positive shut-off.

Every Orbit valve

incorporates a proven tilt-and-turn operation, that eliminates seal rubbing, which is the

primary cause of valve failure. When an Orbit valve is closed, the core is mechanically

wedged tightly against the seat, assuring positive shut-off. When an Orbit valve begins to

open, the core tilts away from the seat and line flow passes uniformly around the core

face. This eliminates the localize high-velocity flow that typically creates uneven seat

wear in ordinary ball, gate and plug valves. The core then rotates to the full-open

position.

When an Orbit valve begins to

open, the core tilts away from the seat and line flow passes uniformly around the core

face. This eliminates the localize high-velocity flow that typically creates uneven seat

wear in ordinary ball, gate and plug valves. The core then rotates to the full-open

position.